3 Simple Techniques For American Plastics

Wiki Article

The 25-Second Trick For American Plastics

Table of ContentsAmerican Plastics Things To Know Before You BuyUnknown Facts About American PlasticsSome Known Facts About American Plastics.All about American PlasticsThe 20-Second Trick For American Plastics

A little research can assist you with time. It is tough to evaluate its top quality at initial glance with the look of HDPE pipe installation, numerous problems are revealed when making use of, so we can only have a proper judgment after usage. It is needed to pick HDPE pipe fittings made by a professional producer with a good track record and reputation.

A technological specialist is necessary for an excellent product, specifically in the production industry, since a little mistake will certainly cause the failing of the entire project. HDPE pipes can replace concrete pipelines in field systems to conserve time and cost of fixing busted or ruptured pipes. HDPE pipe is also a more economical option compared to other piping materials in regards to operating and installation costs.

Indicators on American Plastics You Should Know

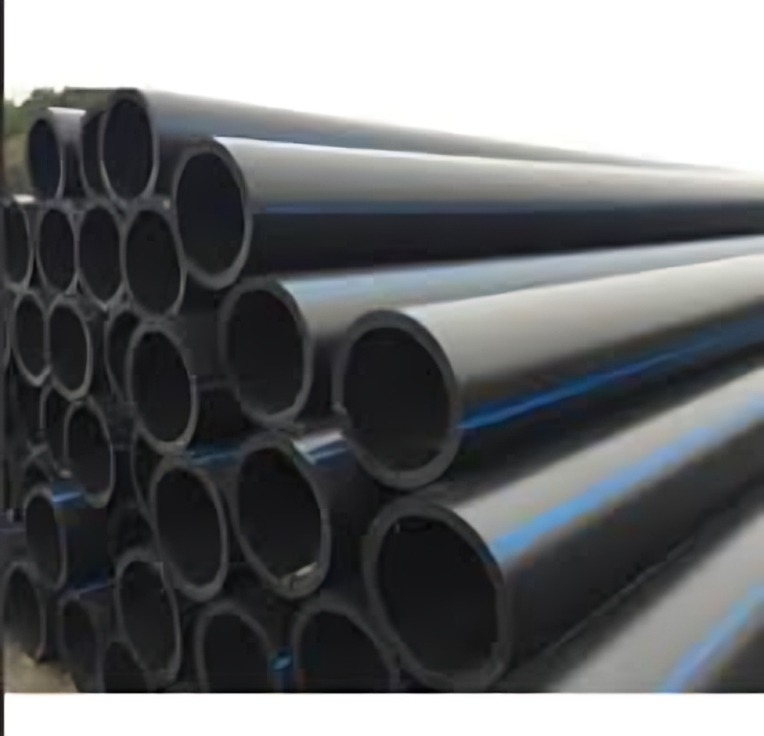

HDPE pipes are made with strong straight or rounded sections. It is made of lightweight products that are simple to transfer and does not call for heavy installation equipment such as heavy cranes. The combination of lightweight and flexible frameworks makes it ideal for earthquake-prone areas. The pipelines are not weak and can be conveniently put right into a curved area without additional jointing or welding.It has reduced stress and anxiety and stormy disturbance, specifically at high circulation rates. Its 'non-adhesive' characteristic makes it excellent for keeping the homes of hydraulic liquids. Also HDPE tin tubes are formed in 2 stages to smooth out the inside. Chemicals immune to HDPE pipes can contaminate the pipe. The pipeline does not deal with chemicals and does not shed warm or electricity.

HDPE pipelines are normally strong and immune to damages brought on by external tons, high stress or vibration - https://free-weblink.com/American-Plastics_254084.html. The pipes can hold up against handling and bend even in winter. Safe eye liner HDPE inner tubing Smooth Line Pipeline Sliding lining utilizing roller mixes Pipe surge Plastic plumbing systems Construction of new pipes Corrosion resistance, no dripping, high resilience

Heat combination, while its difficulties exist, can develop solid and reputable joints. Responses: The stamina and sturdiness of HDPE can be gauged by its ability to withstand temperatures of around 248F in the brief term and even a continuous 230F. If your application includes gas and fluid to access and elevate those temperature levels, HPDE piping is a reliable option.

American Plastics - Truths

For instance, a safe and clean water line/potable water pipeline is always dark with blue red stripes and pipelines passing through liquids, liquids under pressure, and process gases are always loaded with a yellow or black coat with yellow lines. HDPE pipeline product have actually been used in the general sector for over 50 years and their outcomes are astonishing, building self-confidence amongst producers that they are more concentrated on HDPE pipeline options.Times since 1991 Elimination of resin needs with gauge and adjustment. In the tension fracture resistance test the cell division requirements were damaged. For that reason, it is practical to end that HDPE pipeline built today may have.

Each dimension group is made bearing in mind the needs of pressure, flow price, and ecological elements of the designated application. By matching the correct HDPE pipe dimension to its use, engineers and professionals can maximize efficiency and extend the life-span of their piping systems. Measurement and size are related ideas in the context of HDPE pipelines.

The Basic Principles Of American Plastics

As stated earlier, pipes with lower SDR values are able to endure greater stress, which is a vital consideration in the choice procedure for tasks that entail high pressure or critical applications. high quality hdpe pipe. Choosing a pipe with an unacceptable SDR can lead to system failure, safety and security risks, and costly repair services. Selecting the appropriate HDPE pipeline size is important for the success and effectiveness of any type of piping system

Application Specifics: Customize your pipeline dimension option to the certain demands of its application, whether for community, industrial, or other uses. Understanding just how the HDPE pipe will certainly be used, the expected circulation prices and the pressure demands are critical. High-pressure applications may require a pipe with a better wall surface thickness to stand up to the look what i found internal tensions, while a lower-pressure, high-flow system may focus on diameter size to decrease rubbing loss.

The Single Strategy To Use For American Plastics

Adhere to these actions: Evaluate the Application: Determine the pipe's intended use, including ecological elements and service conditions. Compute Flow Prices: Use industry-standard computations or software application to estimate the peak and average flow rates. Understand Stress Requirements: Identify the pressure ranking needed based upon system demands. Describe SDR: Inspect the basic measurement proportion to find a pipe that can deal with the required stress.Picking the best HDPE pipeline dimension is a fragile balance between countless technical requirements and useful needs - https://www.robertehall.com/profile/danecoffman797013032/profile. Nonetheless, with cautious factor to consider and precise computations, you can make sure the size of the pipeline you pick will certainly offer your needs effectively and successfully. Selecting the proper HDPE pipeline dimension is important for system efficiency, durability, and cost-effectiveness

Understanding these aspects will certainly make sure ideal efficiency and compatibility throughout your piping system - hdpe pipe suppliers Midland TX. The awaited circulation rate or volume of the fluid being transported is among the main determinants in pipeline size selection. A pipeline that is too tiny can restrict circulation, triggering stress loss and potential obstructions, while an extremely big pipe may bring about unneeded cost and minimized system efficiency

Report this wiki page